What we do

HASSTEC’S CONTRACT MANUFACTURING SERVICES

Being a part of Hasstec, you'll be doing work that you can be proud of. Your contributions will enable thousands of people to live and work more safely, benefiting from the products you will help manufacture, which are deployed in sectors such as Medicine, Electronic Products, Check Parts, Solar Systems, and more.

CUSTOM WIRE HARNESSING

HASSTEC's wire harnessing services are ideal for a wide range of projects, from simple two-wire assemblies to complex, large-scale wire harnesses. Our expertise in wire harness manufacturing is highlighted by the engineering support and assistance with component selection we offer.

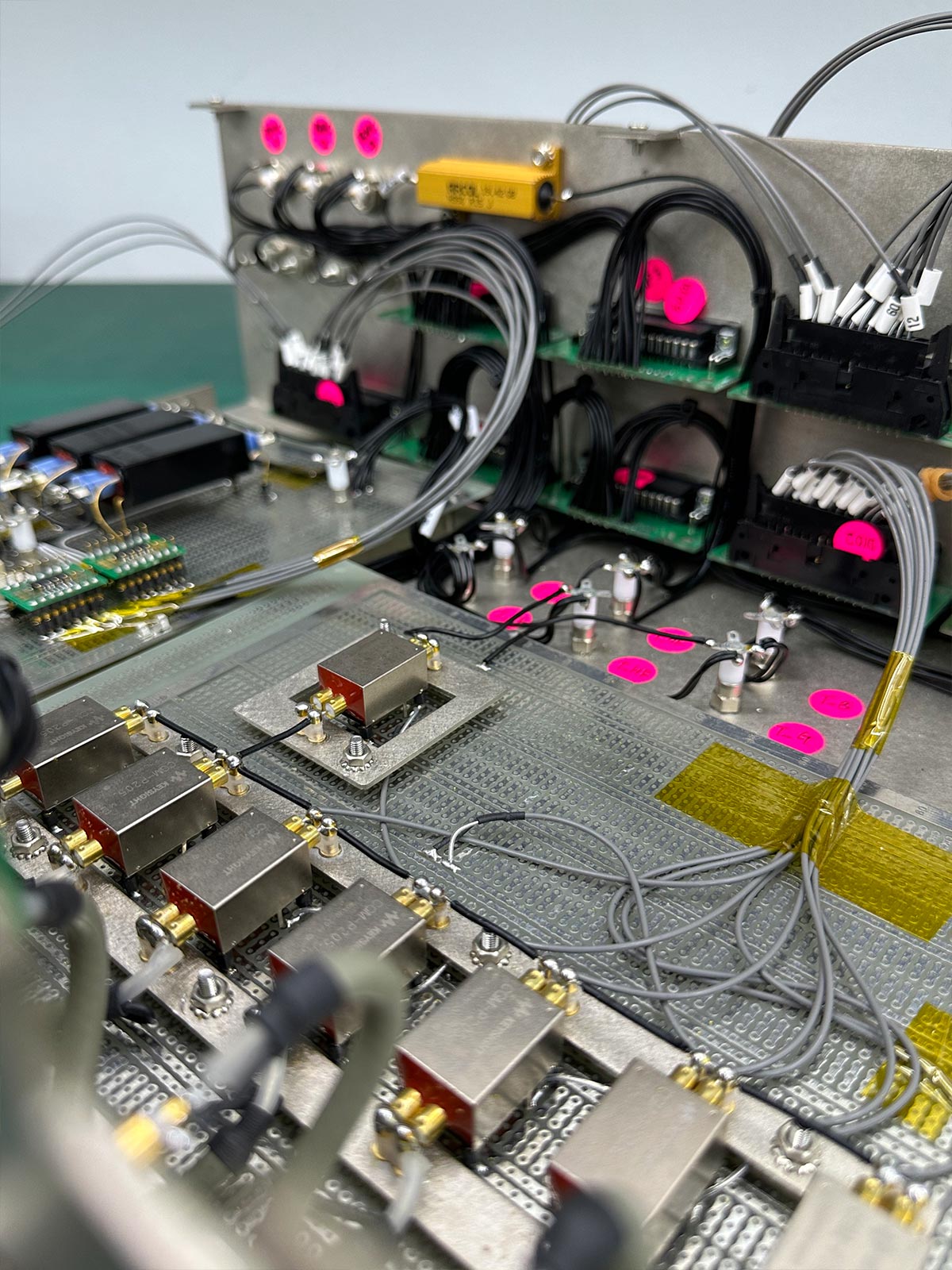

TURNKEY CABLE ASSEMBLY

Obtaining your turnkey cable assemblies from HASSTEC is a straightforward, dependable, and cost-effective solution. Simply provide us with your prints or part drawings, and we'll handle the rest. HASSTEC also offers component sourcing, engineering support, and testing services. Explore our custom cable assembly capabilities in more detail.

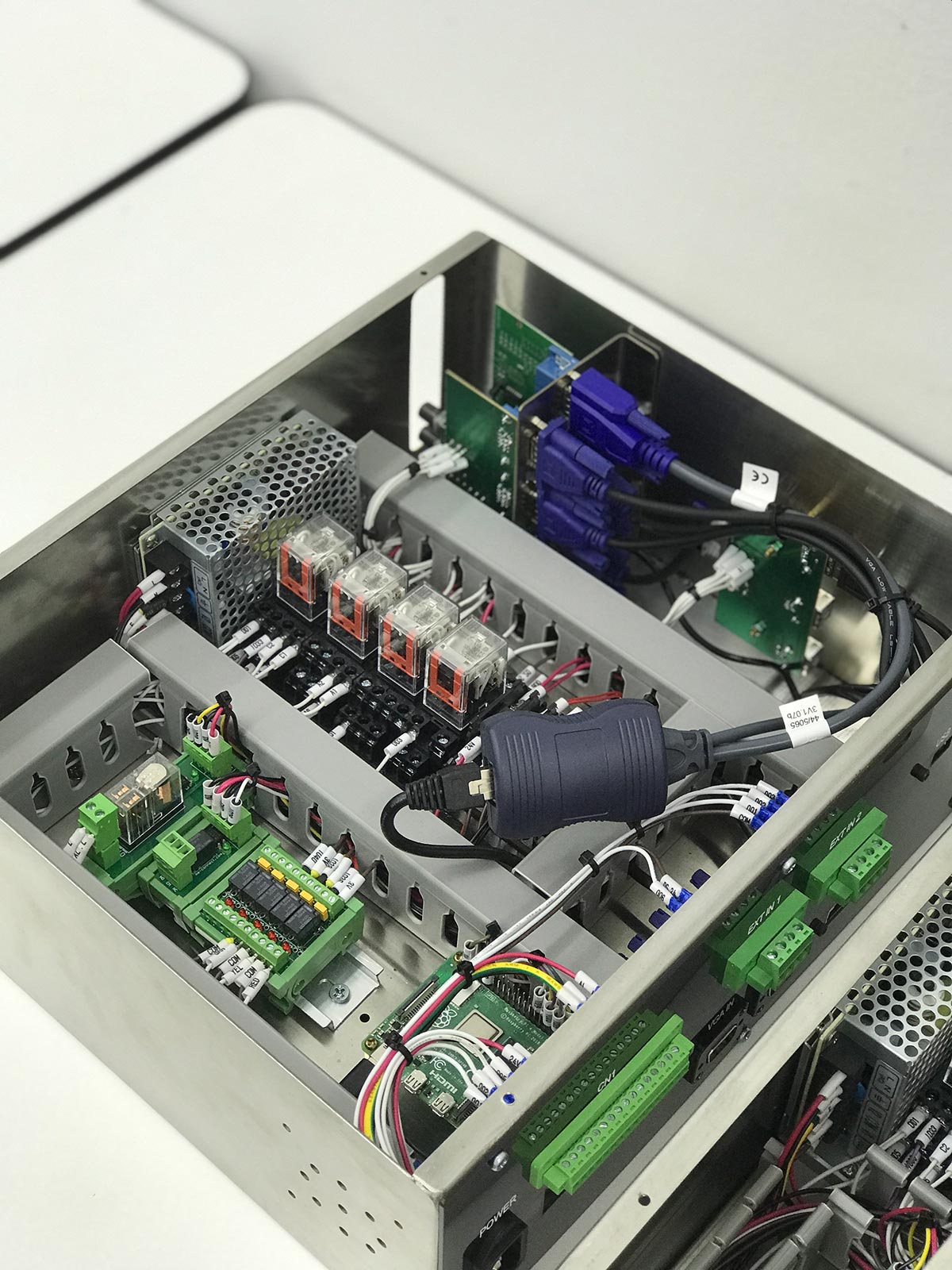

ELECTRO-MECHANICAL ASSEMBLY

HASSTEC excels in providing electromechanical assemblies, including:

>Box Builds

>Enclosures

>LED Assembly

>Switch Assembly

>Power Panel Assemblies

>Fan Assembly

LEAD WIRE ASSEMBLY CAPABILITIES

HASSTEC's lead wire assembly capabilities encompass:

>Working with wire gauges from 4 AWG to 32 AWG

>Performing both single end crimps and double end crimps

>Handling both open barrels and closed barrels

>Utilizing insulated terminals and non-insulated terminals

>RF Cable assemblies

>Wire Soldering

SEMI-AUTOMATIC WIRE & CABLE PROCESSING

Wire processing and cable processing is about more than just wire cutting, cable cutting, wire stripping, and cable stripping. At HASSTEC, trained personnel perform these tasks quickly, accurately, and using state-of-the-art equipment. Furthermore, we provide wire crimping and soldering services.

ENGINEERING SUPPORT

HASSTEC is not just an electronic contract manufacturer; we serve as an extension of your engineering department. This is why prominent companies across various industries have integrated us into their supply chain.

HASSTEC's engineering support capabilities encompass:

>Recommendations for cost-saving through part design, component, and material changes

>Research and sourcing for alternative parts

>Risk assessment and BOM scrubs

TESTING & INSPECTION

HASSTEC's testing and inspection services cover wire harnessing, custom cable assembly, and electro-mechanical assembly to ensure product safety and industry-standard compliance.

HASSTEC’s testing services include:

> Continuity testing

Continuity testing measures the resistance between two points in ohms. Low resistance indicates a closed circuit with electrical continuity, while high resistance indicates an open circuit lacking continuity. Continuity testing can assist in identifying unintended connections between two points.

> Hipot testing

Hipot or high potential (high voltage) tests determine the adequacy of electrical insulation in a wire harness or custom cable assembly. Known also as a dielectric withstand test.

MACHINE WIRING AND ASSEMBLY SERVICES

Our machine wiring and assembly service provides comprehensive solutions for assembling, wiring, and configuring various machinery and equipment. We excel in the precise and efficient connection of electrical and electronic components, guaranteeing seamless and dependable machinery operation.

FEEL FREE TO CONTACT US

CONTACT US FOR

CUTTING-EDGE SOLUTIONS

Optimize Your Assembly Processes with Hasstec's Precision Engineering! Contact us now to explore how our decade-long expertise can elevate your Cable Assemblies.